Refrigerators are commonly used appliances; everyone is familiar with. We all know that a refrigerator serves the purpose of keeping the food cold, frozen, fresh, and stored for a long time. But have you ever wondered how does this container-like electric device does this job? It's not like some magic power provides cooling to the refrigerator; many fridge accessories work with coordination, and resultantly refrigerator produces cooling inside it.

There are many types of refrigerator temperature and defrost sensors that regulate the cooling mechanisms of the refrigerator. A refrigerator does not need to produce cooling 24 hours every day. When enough cooling is established inside the refrigerator, the cooling systems can turn off and rest for a while until they are needed again.

Let's take a look at different types of defrost sensors and their working principle.

What are temperature and defrost sensors?

Temperature sensors work by sensing or detecting any changes produced by heating or cooling inside a system. These changes allow them to control the cooling level by turning the cooling system on or off to maintain the temperature inside the compartment. The compressor's speed and motors working behind are altered whenever the temperature sensor detects any change in the maintained environment.

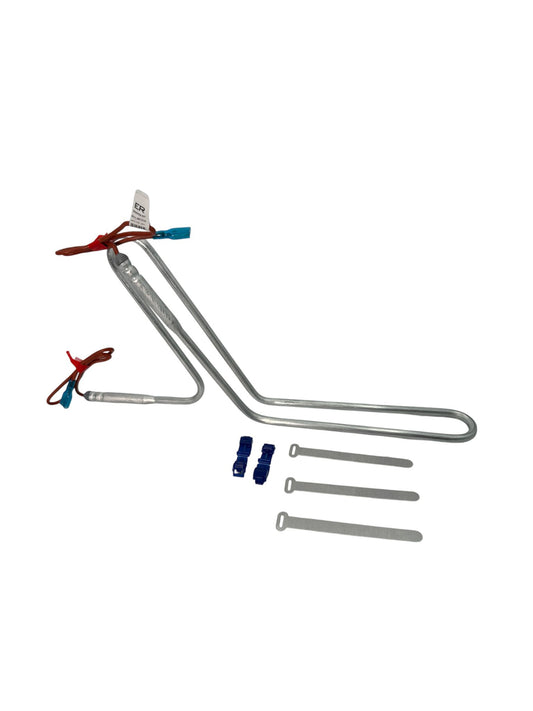

A defrosts cycle defrosts the build-up frost so that the food is stored at the ideal temperature. The interior of the lower unit, which is for keeping the fresh food and not for freezing, never falls below the freezing point. Still, the cooling evaporator tubes, coils, and plates can develop Frost due to low temperature. So, the defrost sensor detects the Frost developing on different parts and a defrost cycle gets rid of the Frost to save the interior of the compartment from getting frozen.

Types of Refrigerator

We have listed some common types of temperature detectors that are used in modern refrigerating appliances.

- Thermostats

Thermostats are electro-mechanical switches that detect any temperature change. These are contact-type temperature sensors. Their composition is made from nickel, copper, aluminum, and tungsten. Thermostats detect any temperature change, and the metallic strips bend, causing the ON or OFF action of the cooling systems.

- Negative Temperature Coefficient (NTC) Thermistors

These are thermally sensitive resistors, as their name shows. They work by changing resistance as soon as a rise or fall in temperature is detected. When the temperature inside the refrigerator increases, the resistance is decreased, causing the cooling cycle to turn on.

- Resistance Temperature Detectors (RTDs)

These defrost sensors are commonly made up of Platinum. They have high resistance characters and work by detecting changes in resistance along with the temperature.

- Thermocouples

One of the most commonly used temperature sensors is thermocouples. They are made up of two metallic wires, and the change in voltages between them depicts variations in temperature. Thermocouples are easy to use.

- Semiconductor-Based Sensors

These are the least used sensors because of the lowest accuracy in temperature changes detection. These sensors are fitted inside the Integrated Circuits of the main boards of refrigerators.

Bottom line

Accurate working of the temperature and defrost sensors is a must to ensure quality cooling in a refrigerator. We recommend you to choose the appliances wisely by checking refrigerator parts thoroughly. After all, a good cooling system is what you need in your refrigerator.