The latest technology concerned with electric motors of the compressors is inverter technology. Inverter technology has brought many benefits for users. Let's get to know what an inverter compressor is and how does it work?

What is an inverter compressor?

A compressor is a machine that is operated mechanically to increase the fluid pressure and reduce the volume. Most of the time, gas works as a fluid. An inverter is an electric device converting DC (direct current) to standard household AC (alternating current). An inverter compressor is a gas compressor that works with an inverter.

Inverter compressor technology

The inverter controls the speed of the motor and regulates the temperature. The inverter compressor units have a variable frequency drive, also called the inverter drive. This drive works to alter the speed of the electric motor that is rotating. This leads to the compressor controlling the heating or cooling output of the system.

The drive works by converting the incoming current and producing the draft of the required frequency. This technology helps in making the units quiet and lowering the operating cost.

Working principle of inverter compressor

It is either a scroll or reciprocating compressor. The compressor uses the drive to control the cooling capacity. It is done by capacity modulation to reach the requirement.

The inverter drive manages the speed of the compressor. Compressors are usually designed to run at different speeds or frequencies, and this drive makes the best use of it.

To ensure proper rotation, good oil management is also required. The turn-down ratio varies based upon the system manufacturer and configuration. The DC inverter gets supply from a single-phase and then works on converting it.

Applications of Inverter Compressor

This technology is favorably used in many air conditioning and refrigerating systems.

1.Air handling units

These systems operate in various buildings and offices. The modulation of capacity in such places seems to save lots of energy and becomes affordable too.

2.Close control units

These are systems that maintain the temperature of the electronic equipment and IT. They work to stabilize the temperature of systems, reduce the internal heating and let the system stay compact.

3.Process cooling

This occurs at the industrial level, where large pieces of machinery require temperature balancing.

4.Variable refrigerant flow

VRF is popular heating and cooling unit currently using inverter technology on a large scale.

5.Dual inverter compressors

The dual or twin inverter compressors consist of two rotors. This divides and lowers the compression load. As a result, the cooling would occur more efficiently, and rotation would be smooth with lesser vibrations. The dual inverter compressor has two chambers for compression that work with a 180-degree phase difference.

Dual inverter compressors are more advanced and lead to rapid cooling.

What are the benefits of an inverter compressor?

There is consistency in the temperature. The cooling effect is enhanced, and heating up is avoided conveniently.

The inverter compressors are more durable than the rotary ones.

There is a reduction in noise generation.

It saves energy and reduces the charges.

Featured Products

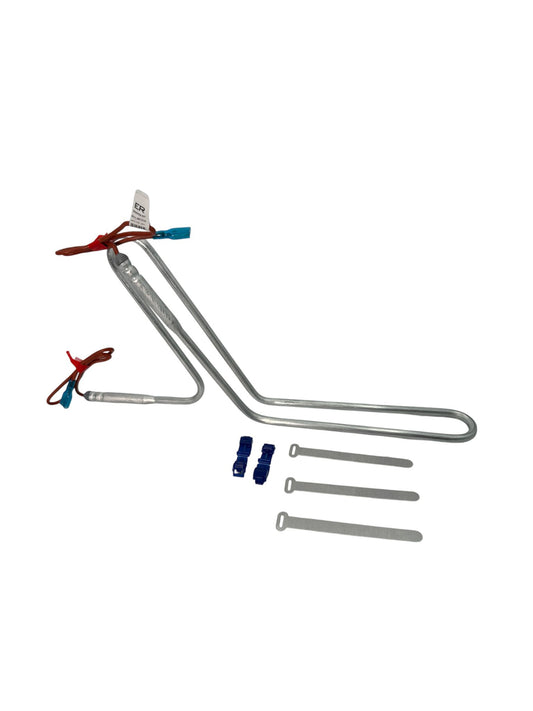

Defrost Booster Kit ER11-00121G, For Samsung Side by Side Refrigerators, Cooling & Noises Issues Repair kit

Regular price

67.91 CAD

Regular price

Sale price

67.91 CAD

Unit price

per

Samsung Refrigerator Evaporator Fan Motor - DA31-00146J

Regular price

51.52 CAD

Regular price

Sale price

51.52 CAD

Unit price

per