Any device that is operated continuously can go wrong due to continuous working or any error occurring. A compressor inverter might work improperly. To ensure accurate working, you can carry a test.

What is a compressor inverter board?

When an inverter compressor is installed in a device, the compressor inverter board controls the compressor.

How does the compressor inverter board work?

The inverter controls the speed of the motor and regulates the temperature. The inverter compressor units have a variable frequency drive, also called the inverter drive. This drive works to alter the speed of the electromotor that is rotating.

This leads to the compressor controlling the heating or cooling output of the system. The drive works by converting the incoming current and producing the draft of the required frequency. This technology helps in making the units quiet and lowering the operating cost.

Summary of inverter compressors

They have three windings instead of two, and all of them have similar resistance.

They do not use any overload or relay devices.

The inverter board produces a particular voltage with higher frequency and faster movements of the compressor.

They generate variable capacity and variable speed

The compressor is not directly powered.

How can the compressor inverter go bad?

The inverter failures can cause interruptions in production as well as financial losses. Inverters can malfunction due to several reasons.

Improper installation

When the inverter is installed without a proper guide and instructions in the user manual are not followed, problems occur in installing the inverter compressor.

Inappropriate cable selection

It is advised to install the cable after the recommendation of professionals.

Inappropriate gauges and inline fuses

The wrong choice in the selection leads to the hard-working of the compressor inverter board, and the whole system’s work is affected.

Tests for the compressor inverter board

Although the compressor inverters do the same job as old reciprocating inverters, their testing or troubleshooting is done differently. This technology will prove to be a long-lasting one. To stay, it has to work efficiently and with minimum errors.

If the compressor is not working correctly, the first thing to do is check the resistance of all three compressor windings. If they are good, then the test is positive.

One of the resistance may be open, or maybe they are imbalanced. That’s why the compressor was not working accurately.

The next step is checking the inverter board. This is commonly done in two ways.

1. Checking the input voltage

There are two types of input voltages for the inverter board

1.120 VAC main power supply.

2.4 to 6 VDC control voltage.

If either of these voltages is missing, the compressor won’t run. This might be due to a bad circuit board. The missing voltage is tracked and checked with all the connected devices.

But if both voltages are being supplied and still there is a malfunction, you need to perform the next test.

2. Checking the current draw on the 120 VAC power supply

First, disconnect this supply from the inverter board and connect one of it to the ampere meter. Reconnect it with the inverter board. Look for the results. If the ammeter shows 0, it means the compressor is not starting if it tries to power up, it means the compressor is working.

Testing Advantages

Testing will help in the actual running of the compressor inverter.

Featured Products

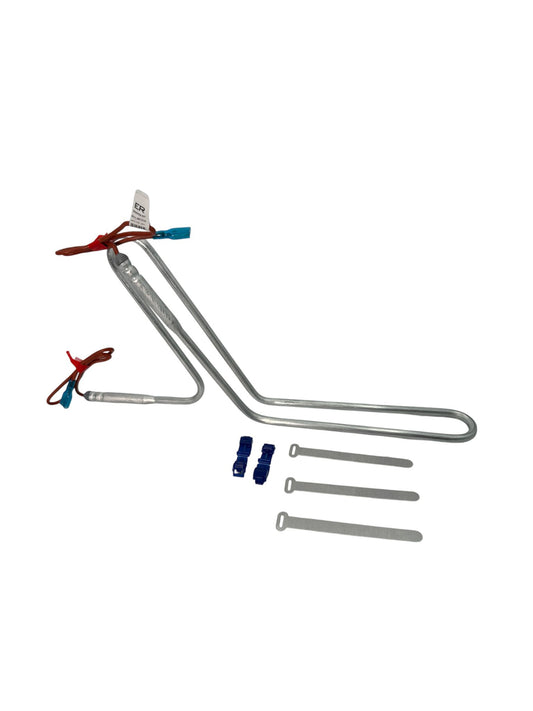

Defrost Booster Kit ER11-00121G, For Samsung Side by Side Refrigerators, Cooling & Noises Issues Repair kit

Regular price

67.91 CAD

Regular price

Sale price

67.91 CAD

Unit price

per

Samsung Refrigerator Evaporator Fan Motor - DA31-00146J

Regular price

51.52 CAD

Regular price

Sale price

51.52 CAD

Unit price

per